有缝钢管和无缝钢管是在钢管行业中常见的两种类型的钢管。它们在制造工艺、性能特点和适用领域上存在着显著的区别。本文将客观、清晰、简洁地介绍有缝钢管和无缝钢管之间的区别。

有缝钢管是通过钢板经过等离子切割或火焰切割等工艺切割成所需长度后,经过辊压成型焊接而成的钢管。而无缝钢管则是通过整块的钢坯经过钢管轧制机的加工,通过热轧或冷轧等工艺制成的钢管。从制造工艺上看,有缝钢管的制造工艺相对简单,而无缝钢管的制造过程则较为复杂。

有缝钢管和无缝钢管在性能特点上也存在着明显的差异。由于有缝钢管在制造过程中进行了焊接,其焊缝处的金属晶粒结构可能会发生改变,从而导致焊缝处的机械性能相对较弱。而无缝钢管由于没有焊接,其整体结构更加均匀,具有优异的机械性能和抗压能力。在一些对强度和耐压要求较高的领域,无缝钢管更常被使用。

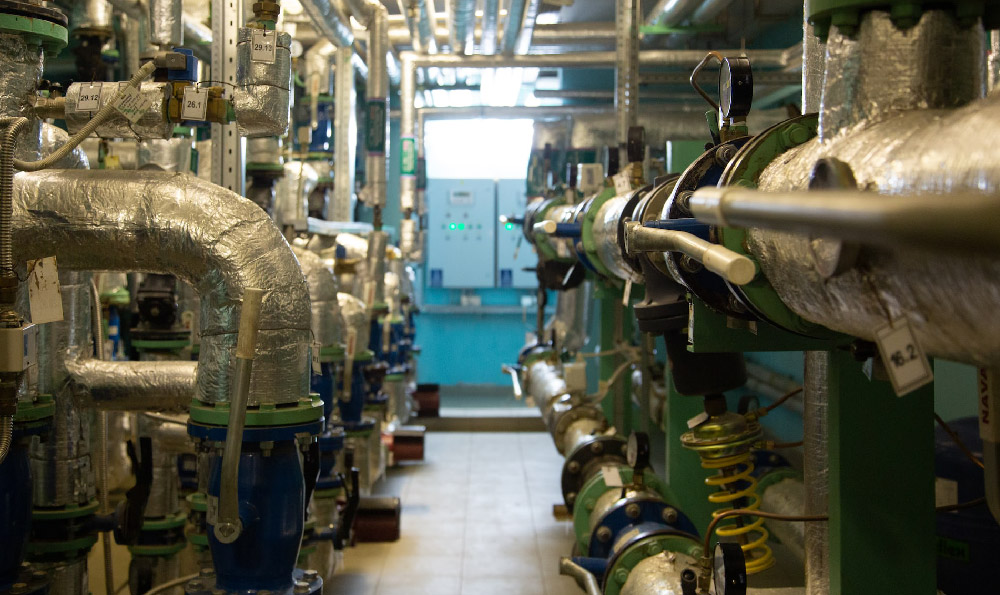

有缝钢管和无缝钢管在适用领域上也有所差异。由于有缝钢管在制造成本上较低,因此在一些对成本要求相对较低的领域,如建筑和民用设备领域,有缝钢管更为常见。而无缝钢管由于其优异的性能特点,更适用于一些对材料强度和耐压要求较高的领域,如石油、化工和机械制造等行业。

有缝钢管和无缝钢管在制造工艺、性能特点和适用领域上存在着明显的差异。有缝钢管的制造工艺相对简单,适用于对成本要求较低的领域;而无缝钢管制造工艺复杂,具有优异的机械性能,适用于对强度和耐压要求较高的领域。了解这些区别有助于选择适合的钢管类型,并在实际应用中发挥其优势。

有缝钢管和无缝钢管的英文缩写

Introduction

Seamless and welded steel pipes are two common types of pipes used in various industries, including oil and gas, construction, and manufacturing. Each type has its own advantages and applications. In this article, we will explore the English abbreviations for seamless and welded steel pipes and discuss their differences and uses.

1. Seamless Steel Pipes (SMLS)

Seamless steel pipes, also known as SMLS pipes, are manufactured without any welded seams. They are made by piercing a solid cylindrical billet and then rolling it into a hollow shape. This manufacturing process ensures the pipes have uniformity in structure and strength, making them suitable for high-pressure applications.

2. Welded Steel Pipes (ERW, LSAW, SSAW)

Welded steel pipes are manufactured by welding the edges of steel plates or coils together to form a cylindrical shape. There are several types of welded steel pipes, each with a different abbreviation

- ERW (Electric Resistance Welded) pipes are produced by passing a current through the steel plate edges, generating heat and melting the metal. The edges are then fused together to form the pipe.

- LSAW (Longitudinal Submerged Arc Welded) pipes are made by using a submerged arc welding process. The steel plates are first formed into a U shape, and then welded in a continuous, longitudinal manner.

- SSAW (Spiral Submerged Arc Welded) pipes are manufactured by forming steel coils into a spiral shape and welding them using the submerged arc welding process. These pipes are known for their strength and ability to withstand high pressure.

3. Differences in Manufacturing and Properties

Seamless steel pipes are produced through a more complex and precise manufacturing process than welded pipes. This results in seamless pipes having a higher cost. However, seamless pipes have improved strength, smooth inner and outer surfaces, and are more resistant to corrosion and pressure.

Welded steel pipes, on the other hand, are more cost-effective and easier to manufacture in large quantities. However, their welded seams can result in potential weaknesses, making them less suitable for high-pressure applications.

4. Applications of Seamless and Welded Steel Pipes

Seamless steel pipes are commonly used in industries where high pressure, high temperature, and corrosion resistance are required. They are widely used in oil and gas exploration, chemical processing, power generation, and shipbuilding.

Welded steel pipes find applications in a variety of industries, including water supply, structural support in construction, and transportation of liquids and gases. They are also used in oil refining, petrochemical plants, and infrastructure projects.

5. Conclusion

In conclusion, seamless steel pipes (SMLS) and welded steel pipes (ERW, LSAW, SSAW) are two essential types of pipes used in various industries. The abbreviations for seamless and welded steel pipes help in easy identification and communication within the industry. Understanding the differences and applications of these pipes is crucial in choosing the most suitable option for specific projects and requirements.

有缝钢管和无缝钢管的价格区别是多少

钢管作为重要的建筑材料,广泛应用于各行各业。有缝钢管和无缝钢管是两种常见的钢管制造工艺,其价格区别直接影响着市场需求和行业竞争。本文将从生产工艺、原材料成本、市场需求等角度探讨有缝钢管和无缝钢管的价格差异。

一、生产工艺的影响

有缝钢管的制造工艺相对简单,通过轧制、焊接等步骤完成,因此成本相对较低,价格更为亲民。而无缝钢管则需要经过更复杂的工艺流程,包括穿孔、轧制、拉拔等工序,使得生产成本相对较高,价格也就相应提高。

在制造有缝钢管的过程中,焊接是一个关键步骤。虽然现代焊接技术不断进步,但焊缝仍然存在一定程度的弱点,对一些特殊场合的应用不够理想。有缝钢管在某些需求更高的领域,如石油、天然气输送等方面的应用相对有限,价格自然相对较低。

二、原材料成本的差异

除了生产工艺,原材料成本也是造成有缝钢管和无缝钢管价格差异的重要原因。有缝钢管的制造过程中,常用的原材料是钢带或钢板,由于市场供应较为充足,价格相对较低。而无缝钢管则需要使用特殊的原材料,如钢锭或钢管坯料,这些原材料的采购成本相对较高,直接导致了无缝钢管的价格较有缝钢管更高。

三、市场需求的影响

有缝钢管因其生产成本较低,价格更为亲民,广泛应用于建筑、交通、装备制造等领域。而无缝钢管由于其制造工艺复杂,价格较高,主要应用于高端装备制造等领域。随着经济的发展和产业结构的升级,对高品质、高强度的无缝钢管的需求日益增加,导致其价格相对有缝钢管更高。

有缝钢管和无缝钢管的价格区别是由生产工艺、原材料成本和市场需求等因素综合影响的结果。有缝钢管由于制造工艺简单、原材料成本较低,价格相对较低;而无缝钢管则以其高品质、高强度的特点,在一些特殊领域具有较大的市场需求,价格相对较高。考虑到项目需求和预算等因素,用户可根据具体情况选择适合自己的钢管类型。